Rendered at 13:07:54 05/02/25

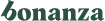

Plasma CNC Torch Height Controller THC Pul /Dir input-output with anti-dive fun.

£157.22 GBP

Ships from

Bulgaria

Shipping options

See item description

Ships from

Bulgaria

Return policy

Full refund available within 30 days

Purchase protection

Catalog info

Payment options

PayPal accepted

PayPal Credit accepted

Venmo accepted

PayPal, MasterCard, Visa, Discover, and American Express accepted

Maestro accepted

Amazon Pay accepted

Nuvei accepted

Shipping options

See item description

Ships from

Bulgaria

Return policy

Full refund available within 30 days

Purchase protection

Catalog info

Payment options

PayPal accepted

PayPal Credit accepted

Venmo accepted

PayPal, MasterCard, Visa, Discover, and American Express accepted

Maestro accepted

Amazon Pay accepted

Nuvei accepted

Item traits

| Category: | |

|---|---|

| Quantity Available: |

10 in stock |

| Condition: |

New |

| Country/Region of Manufacture: |

Bulgaria |

| Brand: |

Dani THC |

Listing details

| Shipping discount: |

No combined shipping offered |

|---|---|

| Posted for sale: |

More than a week ago |

| Item number: |

1720760307 |

Item description

Plasma CNC Torch Height Controller.

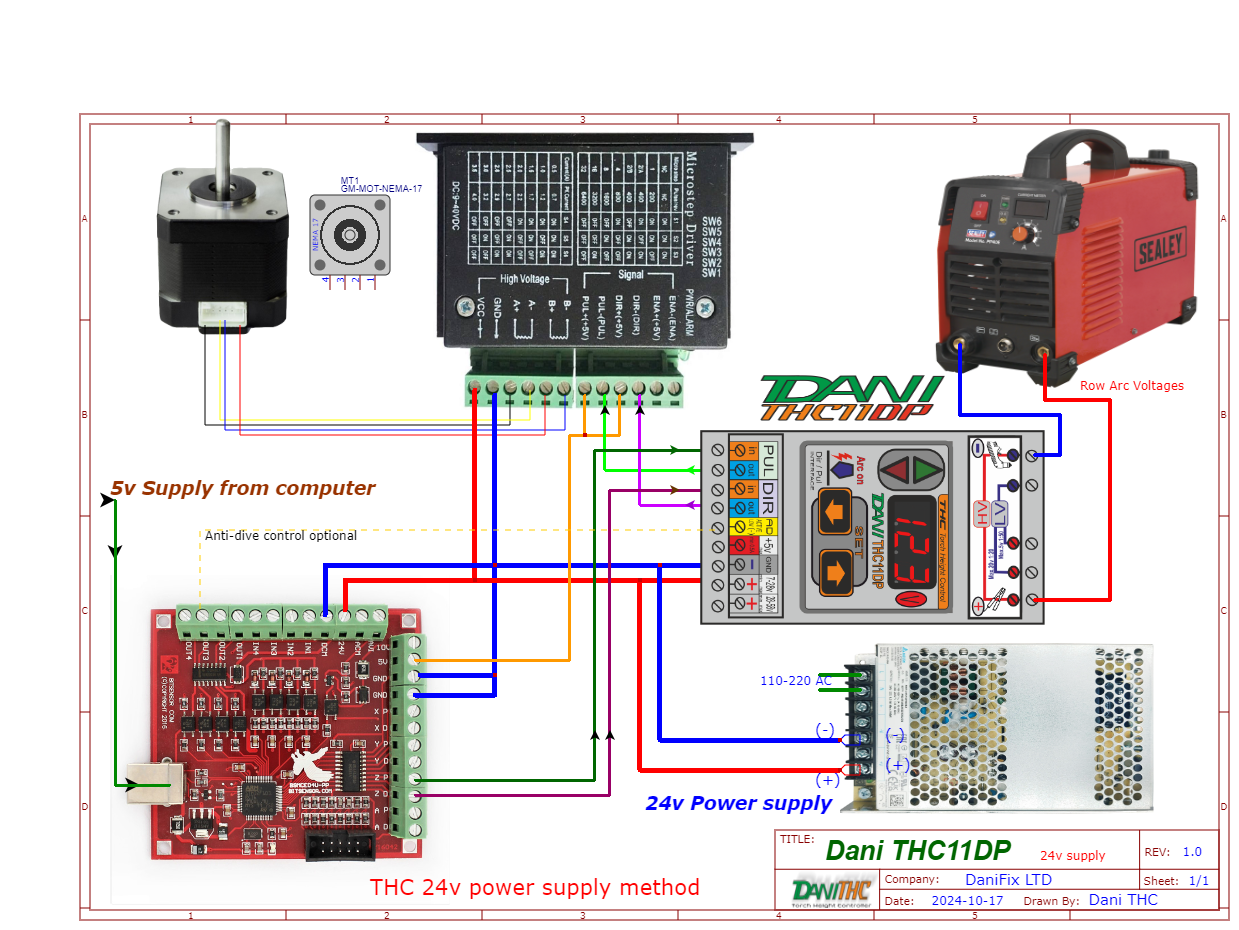

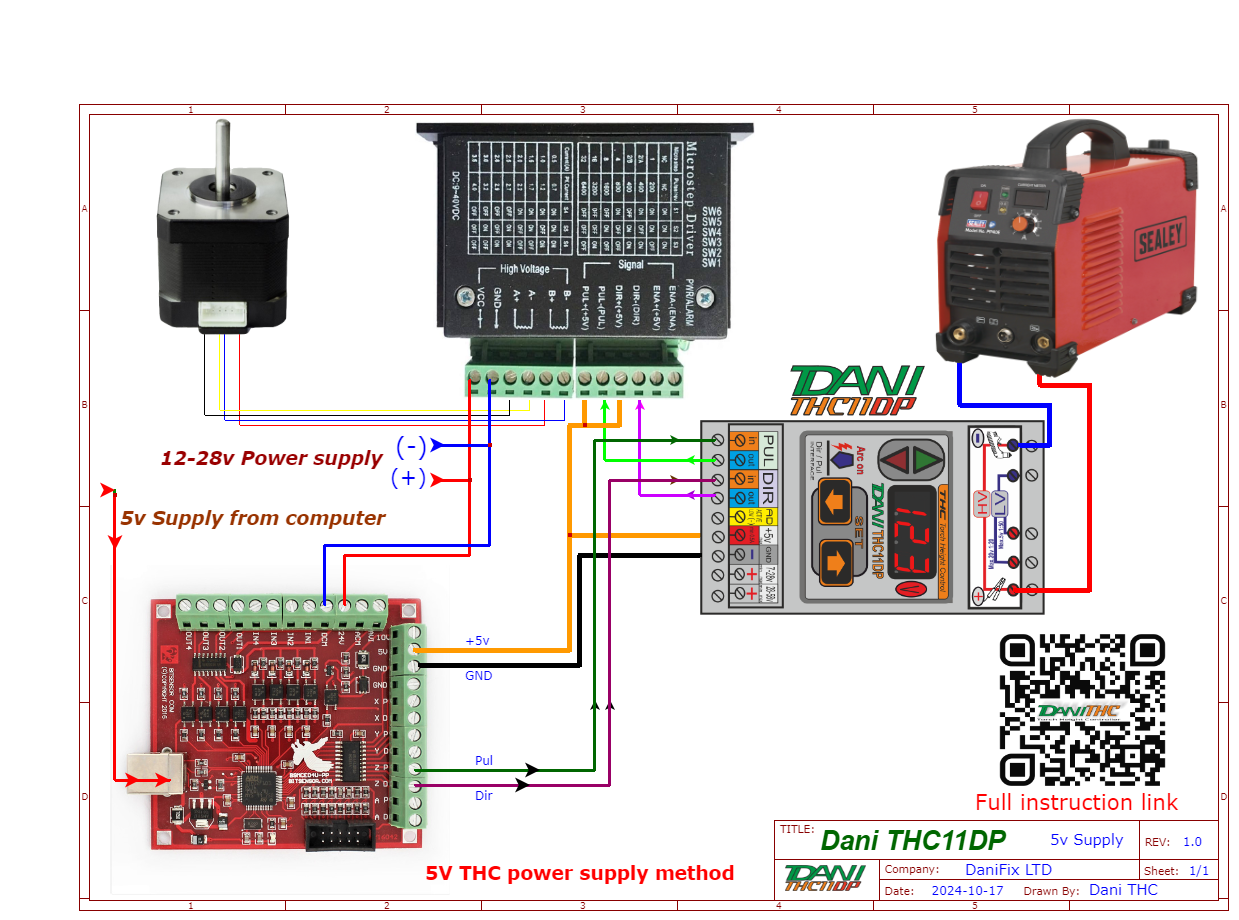

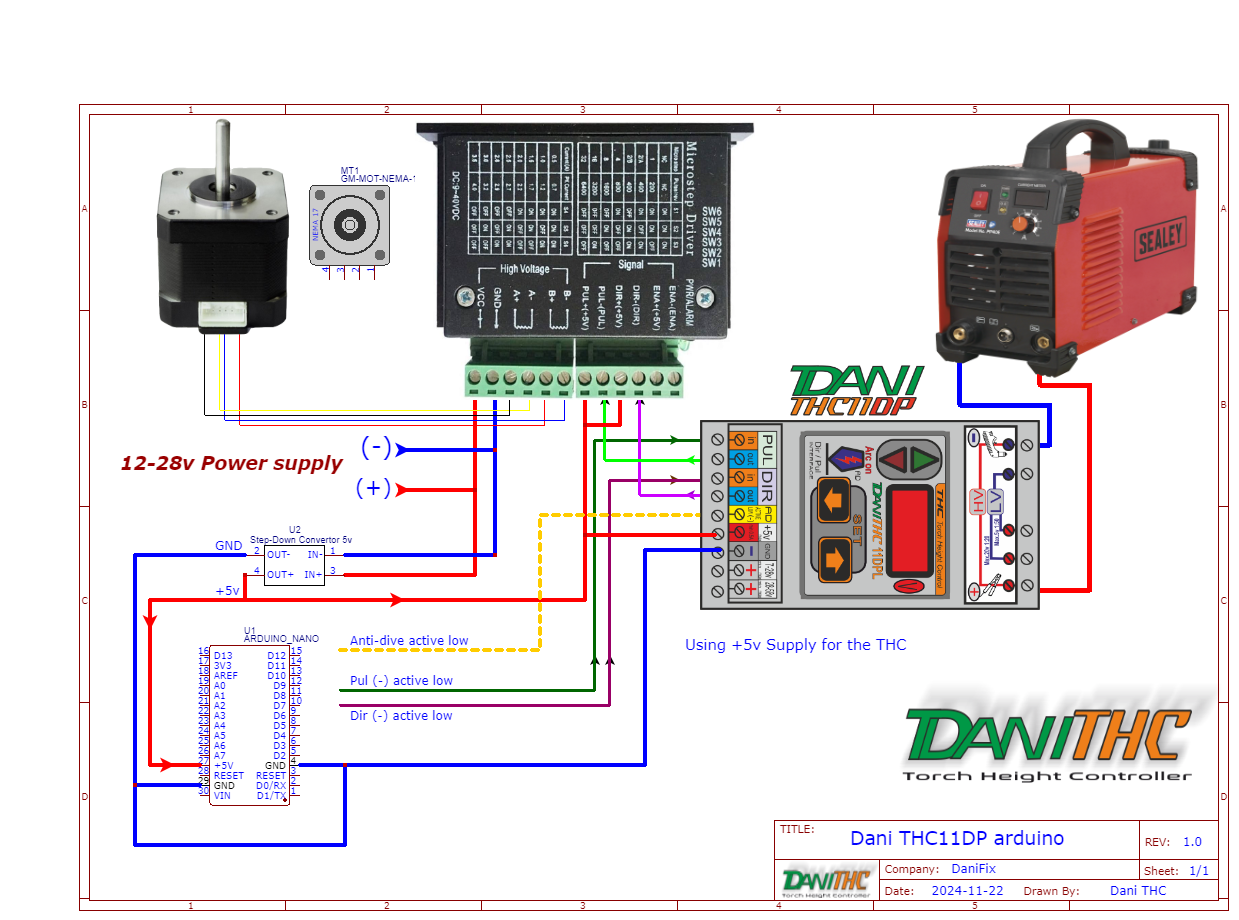

Dani THC11DP (Dir/Pulse input /output interface with anti - dive function ).

Principal of work :

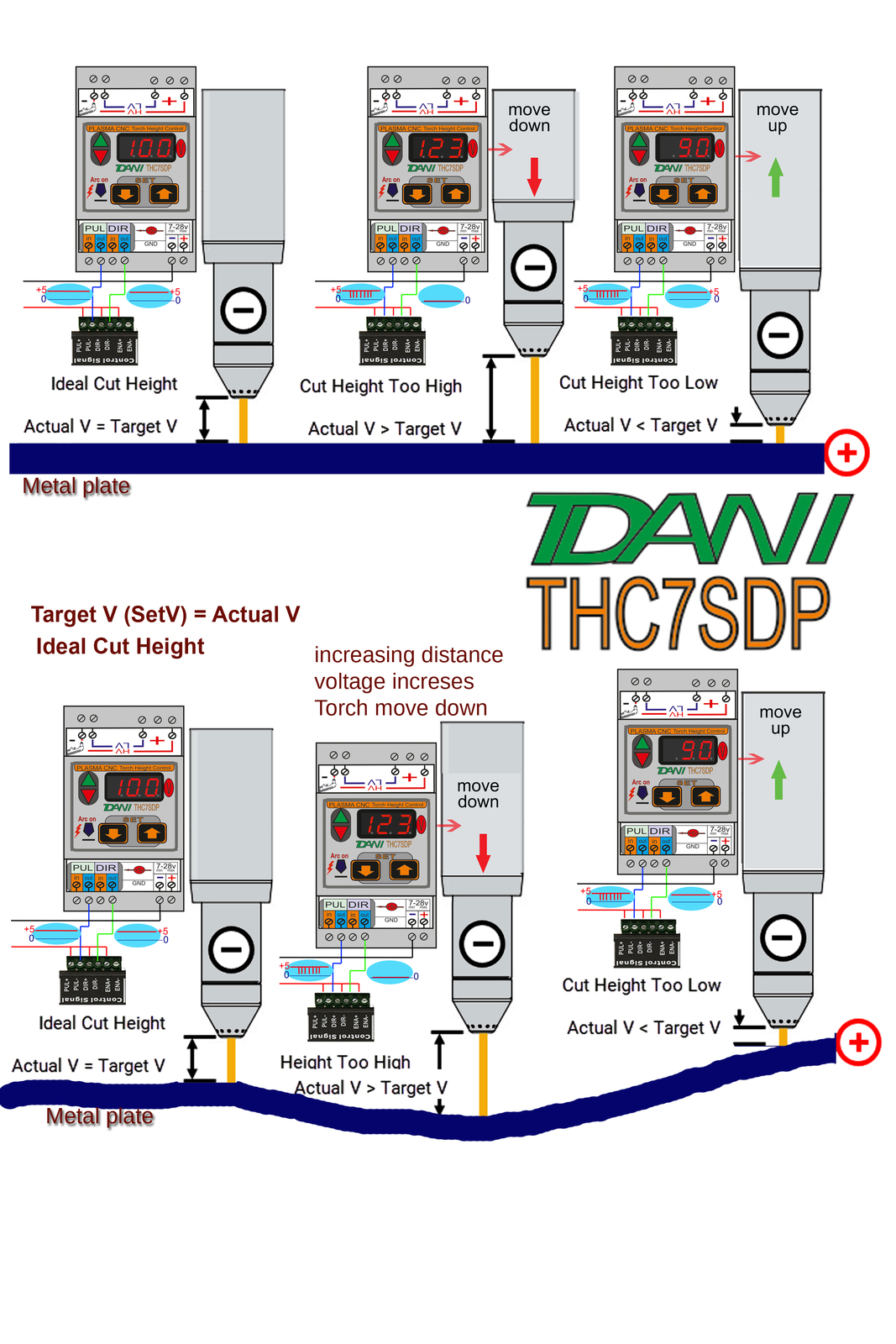

Plasma machines use a constant current power supply for cutting steel. While the current of the plasma cutters is constante (adjustable by operator ) the voltage changes, when the distance between the torch tip and the metal plate changes . When the distance between the torch and cutting plate gets farther, the arc voltage increases and when the torch comes close to the plate the arc voltage will decrease. The Cutting torch voltage can range from 10 to 400 volts (or more) depends of the Plasma cutter's model. The Torch Height Controller (THC) ,will constantly measure the voltage change and will keep a constant distance between the torch and cutting plate by sending a signal to the Motorized Z axis driver to go up , or down.

Dani THC uses internal Voltage Divider, build by high quality components to bring the torch high voltages to a readable safe values and precision filters to protect the CPU from high-frequency interference coming from the cutting torch

The THC calculate the reading values and converting to a control signal for motorized "Z" axis ,Dani THC uses latest generation microcontroller (Atmega328) with adjustable 9 parameters , using 2 friendly buttons ,3 LEDs corresponding to the output signals(Ark ON, UP,and DOWN),3 digits 7 segment led display(solit and high frequency resistable). Dani THC is built with the highest quality components to ensure a safe, durable, and reliable long term operation.

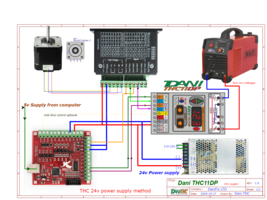

DaniTHC11DP(Dir/Pulse) is a stand alone device .It can control the "Z"axis driver directly without using Mach3 or computer by sending control signals straight to the driver ,to move up or down ,with adjustable speed.

DaniTHC7SDP is Suitable for use with Breakout boards non supporting THC( like USB or LAN serial communication).

The working principle of Dani THC11DP(DIR/PUL with anti - dive function ) is as follows:

When the plasma torch is off and not engaged in the cutting process (during probing or positioning), the THC (Torch Height Controller) is inactive. In this state, the Z-axis movement is controlled by the computer (Mach3). The THC does not interfere with or affect the Z-axis movement during this time.

However, when the plasma torch is on (during the cutting process), the torch voltage activates the THC (Torch Height Controller). In this state, the THC takes control of the Z-axis and maintains a constant desired distance between the plasma torch and the metal plate. The THC continuously adjusts the Z-axis movement based on the feedback from the torch voltage to ensure the proper height is maintained throughout the cutting process.

Anti -Dive Function Principal of work :

A reduced feed rate is often used when cutting small holes or tight angles. This diminished feed rate can lead to an elevation in arc voltage, potentially causing the THC to inadvertently lower the torch into the workpiece. To avert such instances of the torch descending into the workpiece during reduced feed rates, it is advisable to deactivate the Torch Height Control (THC). For a temporary deactivation of the THC, you can utilize the Anti-dive function on the

Dani THC11DP.

Link for pdf operation manuals : https://files.fm/unifixdb

Videos link: https://www.youtube.com/@danifix67911

Dani THC11DP has 17 menu parameters:

Set Voltage (adjust the torch / metal plate distance)

Hysteresis

Delay Time (piercing)

Up distance

High Voltage Limit

Low Voltage Limit

Divider (voltage calibration)

Distance - Speed Reaction

Pulse Polarity

Direction THC17/19 t-25

High Speed Set

Low Speed Set

Auto Anti- Dive

Anti-dive lifting

Smoothness

Test

Low distance limit

Features:

All inputs and outputs are opto isolated.

Power supply (5 - 24 - 58 ) VDC

Measuring Voltages 10-390VDC

Build In Voltage divider (ratio port 1:1, 1:20 or 1:50 ).

Suitable for HF and Non HF Plasma cutters.

Max Input voltages up to 1000VDC.

Real time Torch height correction.

Stand alone device (can be used without computer

Anti - Dive control input

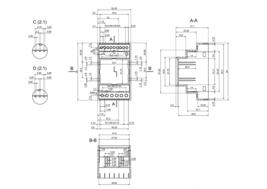

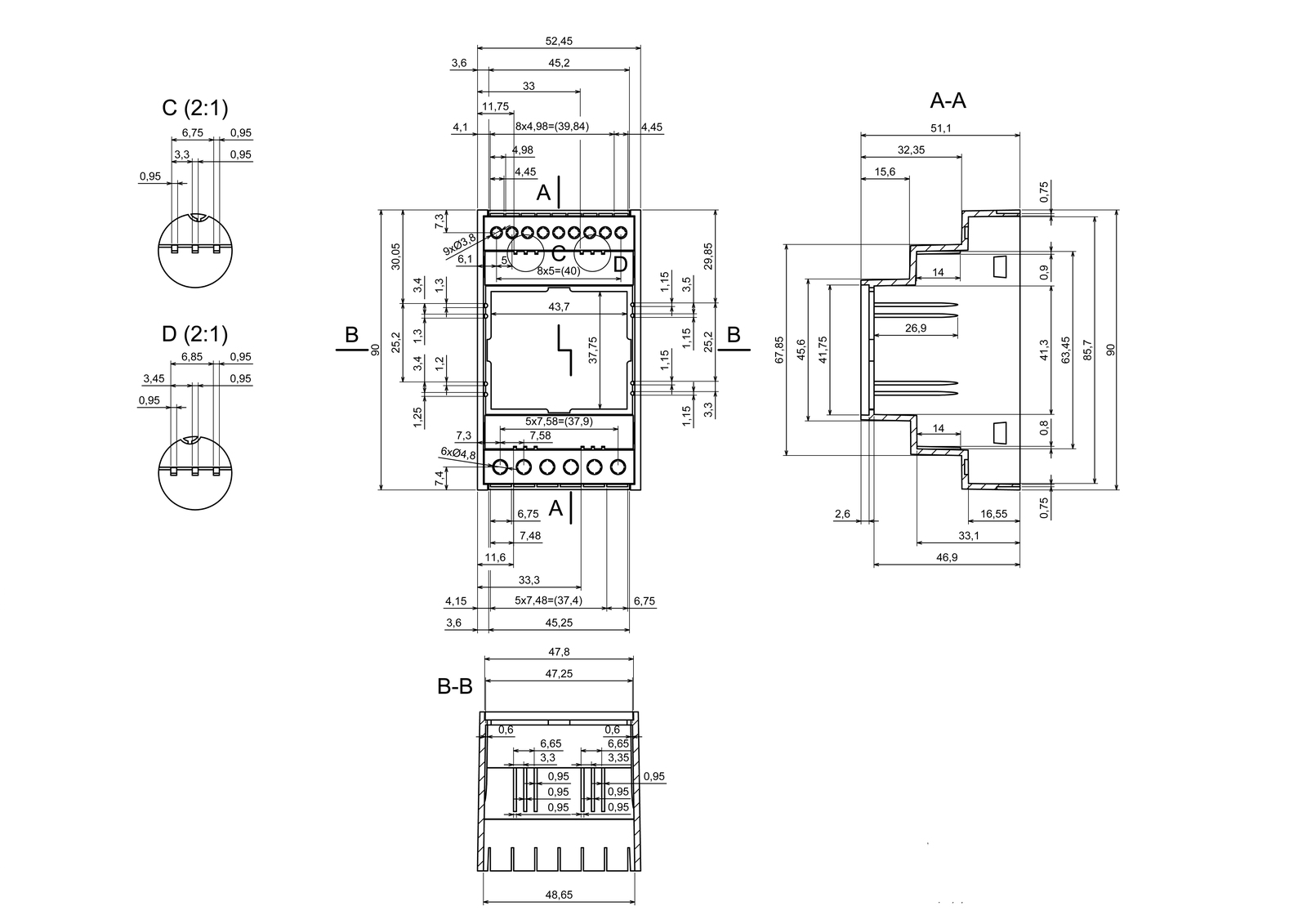

Din rail mountable

Can be used :

MACH3 Compatible

Compatible with all Parallel Port CNC Breakout Boards

Compatible with all USB or LAN CNC Breakout boards

30 Days Money Back Satisfaction Guarantee

Added to your wish list!

- Plasma CNC Torch Height Controller THC Pul /Dir input-output with anti-dive fun.

- 10 in stock

- Returns/refunds accepted

Get an item reminder

We'll email you a link to your item now and follow up with a single reminder (if you'd like one). That's it! No spam, no hassle.

Already have an account?

Log in and add this item to your wish list.