Rendered at 00:07:59 05/04/25

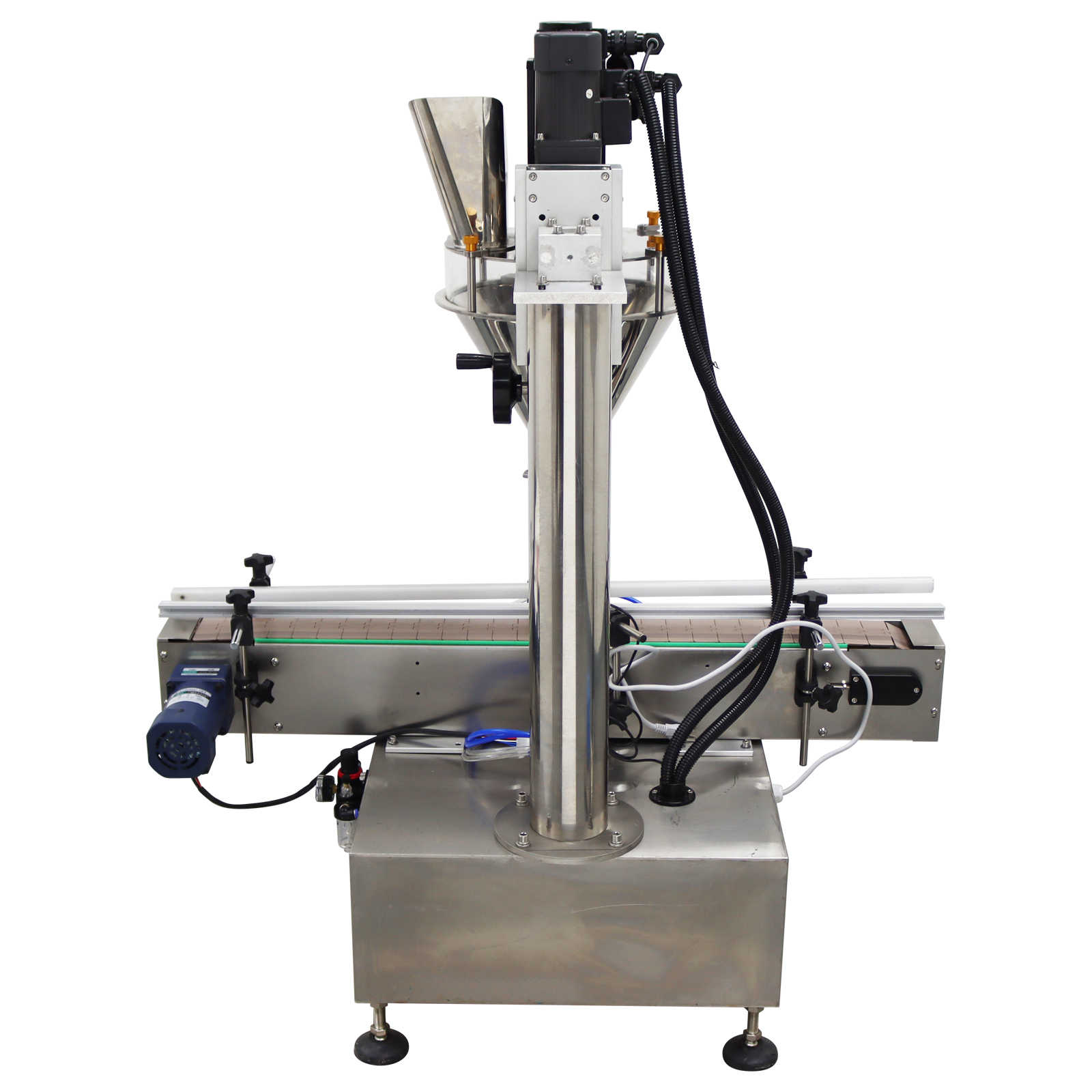

10-200g Automatic Powder Particle Granule Filling Dispense Machine with Mixer

£3,534.91 GBP

Ships from

United States

Shipping options

Seller handling time is 3 business days Details

No shipping price specified to GB

Ships from

United States

Offer policy

OBO - Seller accepts offers on this item.

Details

Return policy

Refunds available: See booth/item description for details

Details

Purchase protection

Payment options

PayPal accepted

PayPal Credit accepted

Venmo accepted

PayPal, MasterCard, Visa, Discover, and American Express accepted

Maestro accepted

Amazon Pay accepted

Nuvei accepted

Shipping options

Seller handling time is 3 business days Details

No shipping price specified to GB

Ships from

United States

Offer policy

OBO - Seller accepts offers on this item.

Details

Return policy

Refunds available: See booth/item description for details

Details

Purchase protection

Payment options

PayPal accepted

PayPal Credit accepted

Venmo accepted

PayPal, MasterCard, Visa, Discover, and American Express accepted

Maestro accepted

Amazon Pay accepted

Nuvei accepted

Item traits

| Category: | |

|---|---|

| Quantity Available: |

Only one in stock, order soon |

| Condition: |

New |

| MPN: |

160358 |

Listing details

| Seller policies: | |

|---|---|

| Shipping discount: |

Items after first shipped each discounted 0.0% |

| Posted for sale: |

More than a week ago |

| Item number: |

1734944375 |

Item description

110V Automatic

tabletop filling machine

The

desktop automatic filling and packaging machine can automatically

complete tasks such as metering, filling, and mixing. It is suitable for

packing granule materials that are easy to flow or have poor

fluidity, such as feed, Rice noodles, white sugar, coffee,

monosodium glutamate and granule additives, etc.

Note:

1.The desktop filling machine is not

equipped with weighing mode (the display screen template shares a set of

templates, although there is an option for weighing mode, it is not

actually available on this machine.)

2.All

weighing related functions in the machine cannot be implemented, and

panel programming is a common set.

?

Product parameter:

Voltage:

110V/60Hz

Power:

1.6KW

Material:

The

surface is stainless steel

Measurement method:

weighing feedback tracking spiral rotation filling type

Packaging weight:

10-200g

(If customers want to achieve different packaging ranges, they

need to change the screw accessories and purchase them

themselves.)

Packaging accuracy:

packaging weight ? 100g, deviation ? 0.5-1g

Product size(Exterior

sizes):

23.6"x22.83"x55.9"

(60x58x142cm)(The

highest height is adjustable)

?

Packaging

weight ? 100g, deviation ? 0.5-1%

Packaging speed:

15-30bags/min

Bin

volume:

15L

Feature:

There are

three

filling modes:

Automatic mode

(after being turned on, the next filling will continue after the

completion of one filling)

Fine adjustment

mode (slowly increase the weight, such as 200 grams. When filling to 190

grams, use fine adjustment, and the material will be slowly filled bit

by bit)

Quantitative

mode (after setting the filling weight, each filling weight will be

equal)

Note:The desktop filling machine is not

equipped with weighing mode (the display screen template shares a set of

templates, although there is an option for weighing mode, it is not

actually available on this machine.)

There are three

options for mixing modes:

Mixing normally

open: The mixing leaves in the hopper will continuously stir without

stopping, including when not filling

Mixing followed

by filling: the mixing function will only be automatically started

during filling

Mixing normally

off: turn off the mixing function

Note:

To

use automatic mode, it is necessary to connect the supporting equipment

conveyor belt, which cannot be achieved by a separate filling

machine.

?

This machine adopts

high quality buckle connection, convenient disassembly and replacement.

Touch screen

man-machine interface: stable operation, anti-interference, convenient

and intuitive operation.

?

This machine is

equipped with an adjustable handwheel. Turning the handwheel clockwise

can raise the filling section to meet the needs of customers at

different heights.

This machine is equipped with a visual window, which allows for a more

intuitive view of the material unloading process and enables timely

addition of materials.

This

machine is equipped with high-quality motors, with stable performance

and low noise.

The

machine is equipped with an enlarged feed inlet for easy filling of

materials.

The

machine is equipped with a chain plate conveyor belt, which is more

wear-resistant and can be used in conjunction with the conveyor belt.

The

machine is equipped with an emergency stop switch, which can stop all

work with one click for greater safety.

Product analysis:

1. Power switch

2. Touch screen

3. Indicator lights

4. Emergency stop switch

5. Conveyor belt speed controller

6. Barometer

7. Adjustment knob for conveyor belt guardrail

8. Conveyor motor

9. Guardrail

10. Discharge nozzle

11. Hand wheel for adjusting the lifting and lowering of the machine

head

12. Mixing silo

13. Feed inlet

14. Material driven motor

15. Storage bin visual window

16. Conveyor belt chain plate

17. Resistance cylinder

Product

safety precautions:

?

To ensure safe production, please carefully

read the following precautions:

1. Use a power supply that meets the requirements of this device, and

ensure that the voltage is stable.

2.After turning off the power switch, there is still voltage in the

electrical control circuit of this machine. When repairing the control

circuit, be sure to unplug the power cord.

3. Do not put your hands into the mixing bucket while working, and pay

attention to personal safety.

4.When there is a problem with the machine, directly press the emergency

stop button to stop all work.

?

Details:

Advantages:

1. The entire machine is made of stainless steel

and can be used for packaging various products.

2. Touch screen man-machine interface: stable operation,

anti-interference, convenient and intuitive operation.

3. The filling adopts a stepping motor moving screw, which has the

advantages of accurate positioning, high accuracy, fast speed, large

torque, long service life, adjustable rotational speed, and good

stability.

4. Mixing adopts high-quality motor: low noise, long service life.

5. High quality material box, clear movement and static of materials at

a glance, and no dust leakage.

6. The replacement of screw accessories can adapt to a variety of

materials, from superfine to large particles. (Our matching screw

can be used for 10-200g.This machine is equipped with a 26MM caliber

discharge screw as standard. If customers have other requirements, they

can consult us to purchase separately.)

Product display:

Item include?1*Automatic

tabletop filling machine

Item Number: 160358

You can make order

with no worry.

Any concerns just feel free to let us know, we'll reply in 24 hours in

normal condition.

Handling Time: Shipping is usually made in 1-3 business days after

payments cleared. Orders are processed from Monday-Friday; Not on the

weekends public holidays.

Warranty: 6 months' warranty for the machines, not for the consumables.

We stand behind our products all the item, so even if your warranty

period has expired, you can still seek for service or technical support

from us with low cost.

Added to your wish list!

- 10-200g Automatic Powder Particle Granule Filling Dispense Machine with Mixer

- 1 in stock

- Price negotiable

- Handling time 3 days.

- Returns/refunds accepted

Get an item reminder

We'll email you a link to your item now and follow up with a single reminder (if you'd like one). That's it! No spam, no hassle.

Already have an account?

Log in and add this item to your wish list.